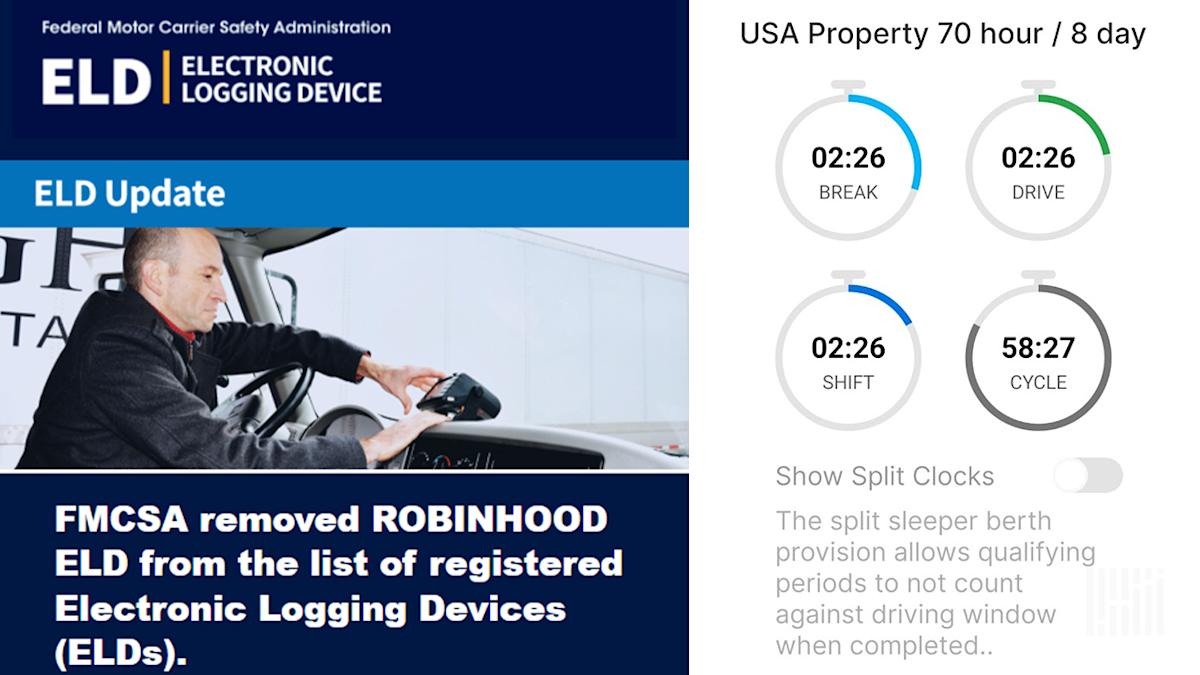

The Federal Motor Carrier Safety Administration removed ROBINHOOD ELD from its list of registered electronic logging devices on Thursday, effective immediately, due to the company’s failure to meet minimum requirements established in 49 CFR Appendix A to Subpart B of Part 395.

Motor carriers using the ROBINHOOD ELD (Model R-HOOD ELD, Identifier: RHD481) have until November 18 to replace the revoked device with a compliant ELD from the registered devices list. Until then, affected fleets must revert to paper logs or logging software to record hours-of-service data.

The revocation is the latest example of how choosing the wrong ELD can create costly headaches for fleets that fail to vet their technology vendors thoroughly.

Unlike European Union systems, which require third-party certification, U.S. ELD providers self-certify that their devices meet the FMCSA’s technical specifications. This process allows ELD manufacturers to register their devices on FMCSA’s approved list simply by attesting that their products comply with the extensive requirements outlined in the federal regulations.

The self-certification approach creates a vulnerability window, allowing non-compliant devices to enter the market and gain customers before the FMCSA discovers deficiencies. The agency only removes devices reactively, after problems are identified through field testing, compliance reviews, or user complaints.

This regulatory gap places the burden on fleets to conduct their own due diligence when selecting ELD vendors, a responsibility many carriers underestimate until they’re forced into an expensive replacement cycle.

For fleets now scrambling to replace ROBINHOOD ELD systems, the financial and operational impact extends far beyond the device cost. The replacement process involves multiple expensive and time-consuming steps:

-

Sourcing and trialing replacement vendors

-

Negotiating new contracts and pricing

-

Physical removal of old hardware and installation of new systems

-

Retraining drivers on different interfaces and protocols

-

Managing operational disruption during the transition

-

Dealing with driver frustration over constant technology changes

Drivers quickly lose patience with fleets that choose unreliable technology vendors. They’re already prone not to love fleet tech in many cases, especially not tech that’s regulatory required. Each failed implementation erodes trust and creates resistance to future system changes, even necessary ones.

The process of finding, evaluating, and implementing fleet technology represents a significant investment in time and resources. Smart fleets understand that cutting corners on vendor selection ultimately costs more than investing in reputable providers upfront.

When evaluating ELD vendors, fleets should prioritize several key factors over lowest-bid pricing:

-

Track record and stability: How long has the vendor been in business? Do they have a history of FMCSA compliance issues? Have their devices been removed from the registry before?

-

Technical capabilities: Does the device meet all current specifications in 49 CFR 395 Appendix A? Can the vendor demonstrate ongoing investment in product development and compliance?

-

Customer support: What level of technical support does the vendor provide? How quickly do they respond to driver issues or system malfunctions?

-

Company values and ethics: Does the vendor demonstrate commitment to regulatory compliance and safety, or do they market features that skirt the edges of legal requirements?

-

Financial stability: Is the company financially sound enough to provide long-term support and updates?

The most expensive ELD purchase is the one you have to make twice. Fleets that focus solely on upfront costs often discover that cheap providers lack the resources or commitment to maintain regulatory compliance over time.

Smart fleets invest time in comprehensive vendor evaluation before making ELD commitments. This includes:

-

Reviewing FMCSA compliance history and any past device removals

-

Testing devices in real-world conditions with actual drivers

-

Checking references from other fleets using the same system

-

Evaluating the vendor’s technical support capabilities

-

Assessing the company’s financial stability and long-term viability

The goal is to select a vendor that will provide reliable, compliant service for years, not months. This approach avoids the costly cycle of removal, replacement, and retraining that plagued fleets using providers like ROBINHOOD ELD.

Beginning November 18, motor carriers continuing to use the revoked ROBINHOOD ELD will be considered as operating without an ELD. Safety officials encountering drivers using the revoked device after that date will cite them for 395.8(a)(1) and place them out-of-service according to Commercial Vehicle Safety Alliance criteria.

Until November 18, enforcement officials are encouraged not to cite drivers using the revoked ELD for “No record of duty status” violations, instead requesting paper logs or using the ELD display as backup to review hours-of-service data.

FMCSA noted that if ROBINHOOD corrects all identified deficiencies, the device could be restored to the registered list. However, the agency strongly encourages carriers to replace the system now rather than wait for potential corrections.

The ROBINHOOD ELD removal continues a pattern of device revocations that have affected thousands of motor carriers. Earlier this year, FMCSA removed multiple devices including TT ELD PT30, ELOG42, and RENAISSANCE ELD, forcing affected fleets through similar replacement cycles.

Each removal drives home the importance of thorough vendor vetting and the risks of choosing ELD providers based primarily on price rather than reputation and compliance history.

For the trucking industry, investing in reputable, stable ELD vendors from the start saves money, time, and driver satisfaction in the long run. The cheapest option often becomes the most expensive when compliance failures force fleets back to the drawing board.

The post FMCSA Revokes ROBINHOOD ELD, The Price Value Dilemma appeared first on FreightWaves.

Leave a Comment

Your email address will not be published. Required fields are marked *